Rollers and cylinders with electrically conductive coatings

With high-tech devices becoming increasingly complex and sensor technology becoming very sensitive in some cases, the requirements in the coating sector have also increased. If electrical charges are generated in the wrong place, for example, this can have serious consequences for the function of a device. Rollers and cylinders with electrically conductive coatings take preventive measures in your processes. Ask us about your rollers and cylinders without obligation!

Advantages of electrically conductive coating

In the area of electrostatic charging, a conductive coating (as a supplement) can provide a remedy. By adding special additives, it is possible to individually influence the surface and contact resistance and dissipate unwanted charges via the coating of a roller.

Your advantages at a glance:

- electrostatic running charges are dissipated/suppressed

- products are protected from damage

- dust accumulation is avoided

- electrical fields in sensitive environments/for sensitive products are avoided

Customized production of electrically conductive coatings

We offer these coatings with electrical conductivity:

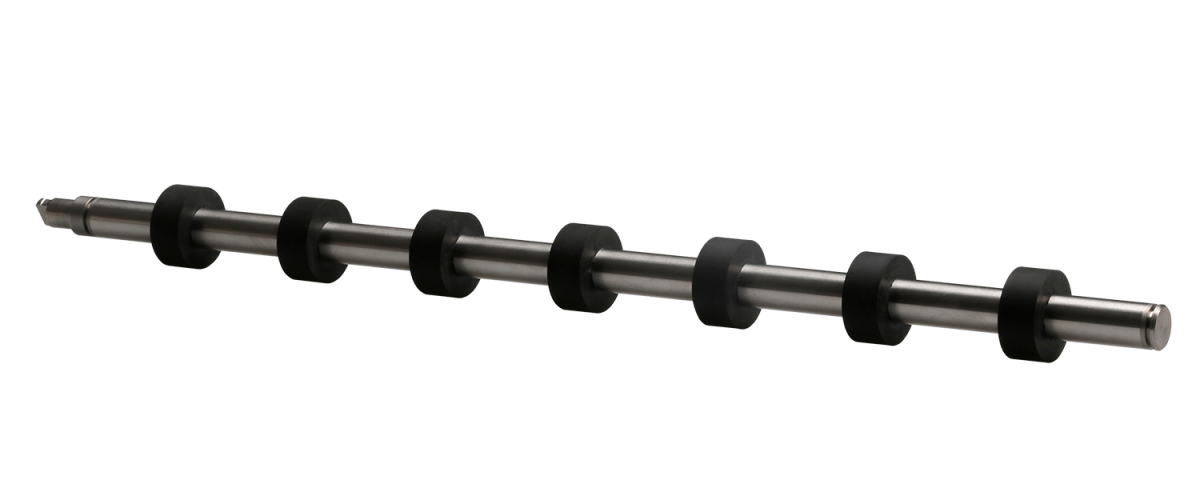

- EPDM

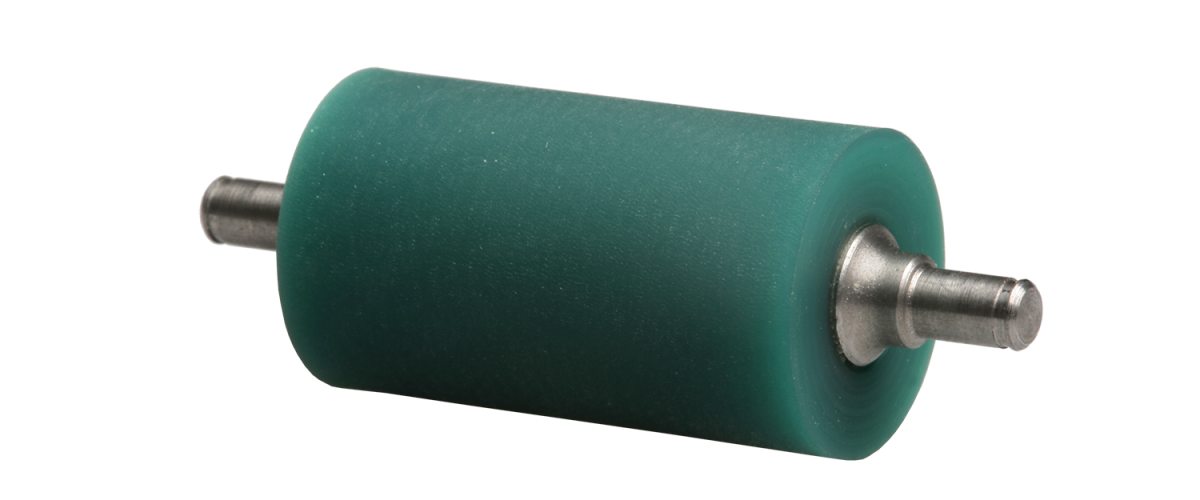

- Polyurethane (PUR)

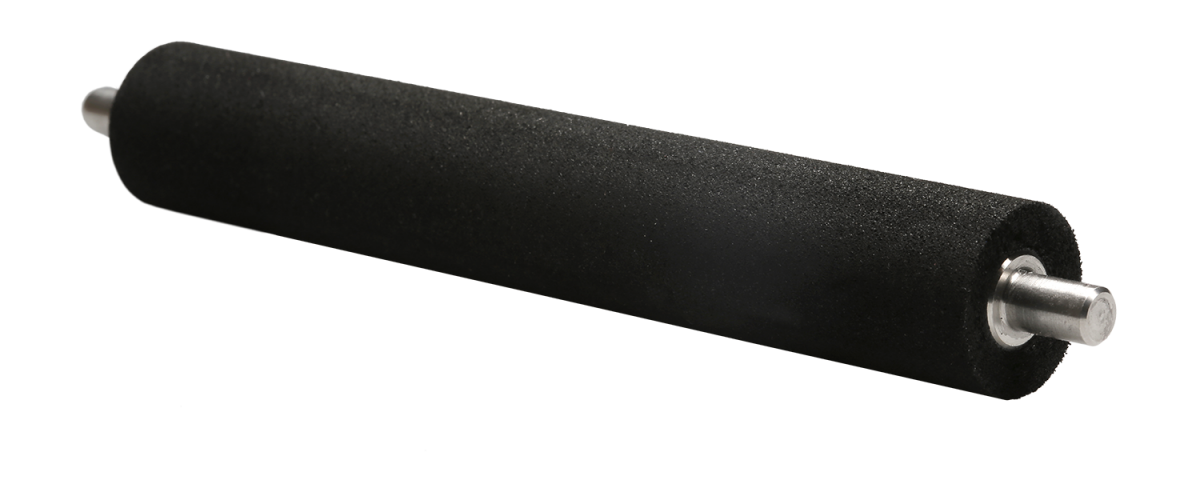

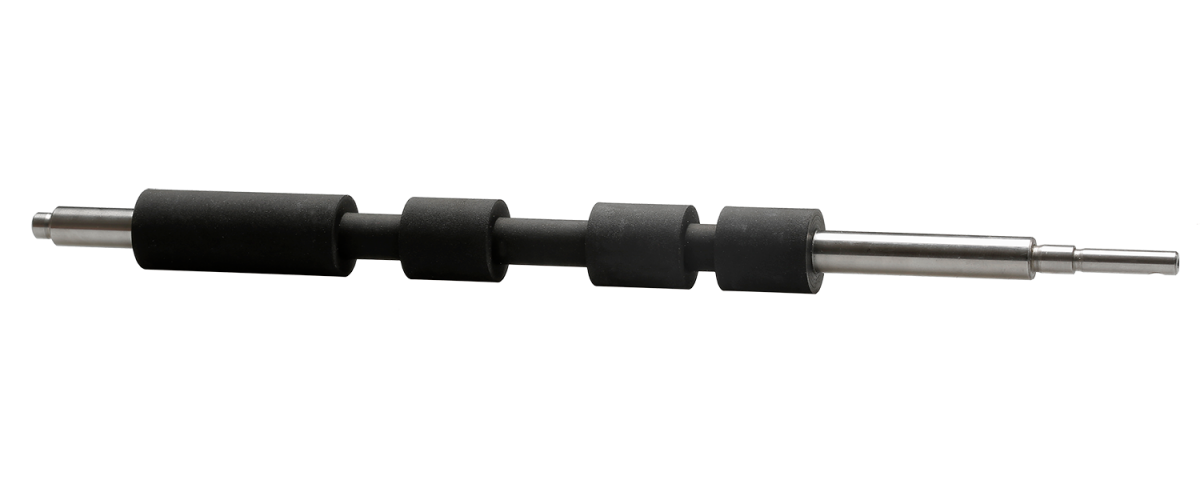

- Polyurethane foam (PUR foam)

Rollers and cylinders with EPDM coating

Electrical conductivity is also becoming increasingly important for rollers and cylinders and is required in various areas. With the right composition, the special coating materials reliably dissipate electrostatic charges. These include, for example, specially treated roller coatings made of ethylene propylene diene rubber, known as EPDM. This material can not only be equipped electrically, but is also characterized by other advantages. These include very good surface resistance to ozone and UV radiation as well as many solvents and chemicals, temperature stability and very good wear resistance.

Rollers and Cylinders with polyurethane or polyurethane foam coating

Polyurethane (also known as PUR foam) meets the highest requirements. Similar to EPDM, the material is extremely wear-resistant, resistant to acids, alkalis and weathering (e.g. UV radiation) and also has good oil resistance. In their standard version, polyurethanes, like all plastics, are insulators and therefore non-conductive. However, we offer you special coatings made of polyurethane and polyurethane foam, which are given electrical conductivity by mixing in additional additives.

Even more rollers and cylinders with coatings

In addition to rollers and cylinders with an electrically conductive coating, we offer you a large portfolio of individually configurable coatings. Discover, for example, rollers and cylinders with silicone coatings or foam coatings. As part of our recycling program, we remove old coatings from your rollers and cylinders, apply new ones and carry out repair work. Please contact us if you have any questions!